Fruit Picking Robots Can Navigate Easily In Orchards and Can Harvest and Monitor Crops

Fruit picking is a labor-intensive task that has traditionally relied on human workers to carefully harvest fruits with precision and care. However, advancements in technology are now paving the way for the development and deployment of Fruit Picking Robots, which are poised to revolutionize agricultural harvesting practices. These innovative machines offer the potential to increase efficiency, reduce costs, and address labor shortages in the agricultural sector.

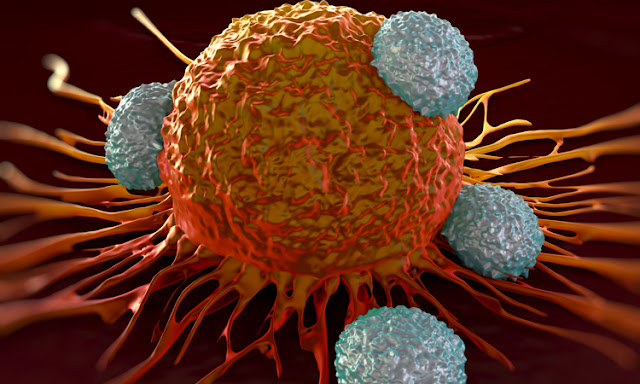

Harvesting robots are designed to mimic the dexterity and judgment of human workers, enabling them to identify ripe fruits, delicately detach them from branches or vines, and handle them without causing damage. These robots combine various technologies, including computer vision, machine learning, robotic manipulation, and sensor systems, to perform these tasks with speed and accuracy.

The Fruit Picking Robots Market is expanding primarily due to the increased need for high production from current farm lands, the paucity of labour, and the growing population.

One of the key technologies employed in harvesting robots is computer vision. Advanced cameras and imaging systems are used to capture high-resolution images of fruit trees or vines, allowing the robots to analyze and identify ripe fruits based on their color, size, shape, and texture.

Robotic manipulation is another critical aspect of harvesting robots. These robots are equipped with robotic arms or end-effectors that can delicately grasp and detach fruits from plants. The design of these grippers is crucial, as they need to exert enough force to remove the fruit without causing damage, while also being flexible enough to adapt to various fruit shapes and sizes.

To ensure precise and gentle handling of fruits, Fruit Picking Robots also incorporate sensor systems. These sensors can detect the force exerted on the fruit during the picking process, allowing the robot to adjust its grip accordingly and prevent any bruising or damage.

The development of harvesting robots is driven by several factors. Firstly, labor shortages in the agricultural sector have become increasingly challenging, particularly during peak harvest seasons. By deploying harvesting robots, farmers can overcome these labor limitations and ensure timely and efficient harvesting of their crops.

Moreover, harvesting robots offer significant advantages in terms of efficiency and productivity. Unlike human workers, these machines can operate continuously, 24/7, without the need for breaks or rest. This allows for continuous harvesting and reduces the time required to complete the process, ultimately improving the overall productivity of the farm.

Harvesting robots also contribute to enhanced fruit quality. By utilizing advanced imaging and sensing technologies, these robots can identify and selectively pick only ripe fruits, ensuring that the highest quality produce is harvested. Furthermore, the implementation of harvesting robots has the potential to reduce costs for farmers.

Although the initial investment in the robots and associated infrastructure may be significant, the long-term benefits outweigh the costs. It is worth noting that Fruit Picking Robots are still undergoing continuous development and improvement. Challenges remain, such as the ability to handle delicate fruits with irregular shapes, adapt to changing environmental conditions, and efficiently navigate complex orchards or vineyards.

Comments

Post a Comment