Bioresorbable Implants Can Also Help To Prevent Complications And Speed Up The Recovery Process

Medical implants, either passive for structural support or for diagnosis and therapy with active electronics, are widely used in surgical applications. Although they have shown long-term biocompatibility, their removal imposes physical, biological and economical burdens on patients. To overcome this drawback, implantable devices exhibiting biodegradation in the body have been developed. These implants disappear inside the body after a certain time of use, and can be replaced with natural bone.

The resorption of Bioresorbable Implants is driven by hydrolysis of the bonds linking their monomers. The amorphous portions of the polymer degrade first, while the crystalline regions remain intact and provide most of their mechanical strength. The monomers are then broken down into lactic and glycolic acids, which are converted to pyruvate and then processed through the citric acid cycle into water and carbon dioxide.

The Bioresorbable Implants Market was valued at US$ 5,543.1 million in 2017 and is anticipated to grow at a CAGR of 7.7% from 2018 to 2026.

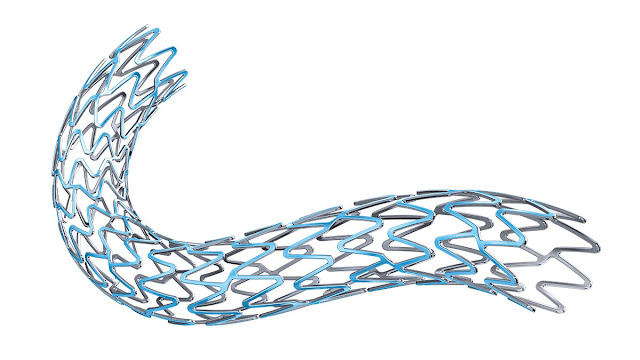

Medical implants have become an integral part of therapeutic medicine and are utilized for various indications such as mechanical support of biological structures in orthopedic and dental surgery, continuous monitoring and feedback of electrical stimulation during neuronal or cardiac procedures, or drug delivery with preservation of arterial wall structure in drug-eluting stents. Traditionally, metal implants are used for internal fixation of fractures.

To overcome these problems and to meet the clinical needs for an alternative, bioresorbable materials have been developed. They can offer a temporary structural function and can be removed after the healing process.

Bioresorbable Implants unlike traditional metal implants, they do not require a follow up surgery to remove them which reduces the cost and time for recovery.

However, the success of these new materials depends on a good match between the rate at which they lose their strength and the rate at which the damaged tissue heals. Any mismatch can result in adverse reactions such as implant failure, fibrosis, or inflammatory responses that may interfere with the healing process and ultimately cause further damage to the injured site.

The degradation of these devices can be influenced by a number of factors such as the type of polymer, the presence of other materials, and its physical properties such as glass transition temperature. These properties can be modified by adjusting the composition and by changing the temperature at which it is exposed to air. Shalby Advanced Technologies and US based Gardner Orthopedics, collaborated in March 2022, for forming Advanced Orthopedic Centers of Excellence in India, Florida, and Fort Myers.

Comments

Post a Comment