Metamaterials A Popular Materials That Have Various Industrial Uses

Metamaterials are engineered materials with properties that are not found in nature. These materials are typically made up of assemblies of multiple elements fashioned from composite materials such as metals and plastics.

Another type is an auxetic lattice, a structure that shows a negative Poisson's ratio, a measure of how quickly the material expands or contracts in response to loading. These structures can be used to enhance energy absorption in body armor or protective sports equipment, drug delivery, stents, or filters.

A third kind of material is a tunable mechanical that is capable of changing its shape in response to a stimulus. This could be a magnetic field, heat, or hydration. The ability to tunable a mechanical one is important, as it will be able to react faster and more precisely to a variety of stimuli. This could lead to devices that are more efficient and responsive, as well as more aesthetically pleasing.

One type of Metamaterials is a hyperbolic structure, a multilayer structure alternating between metallic and dielectric layers. This structure is useful for a number of different purposes including energy absorption, drug delivery, and stents or filters.

This is particularly important for applications that are inherently less predictable, such as wireless charging. It also means that a design team will be able to create an effective electromagnetic filter without needing to rely on expensive and unwieldy RF components.

The global Metamaterials Market, which was valued at US$ 633.31 billion in 2021, is anticipated to increase to US$ 14,265.56 billion by 2030, at a CAGR of 41.6%.

In addition, a tunable one can be designed to reroute electromagnetic waves from one region to another. This allows a designer to focus on specific wavelengths and avoid interference while allowing the device to be more energy-efficient.

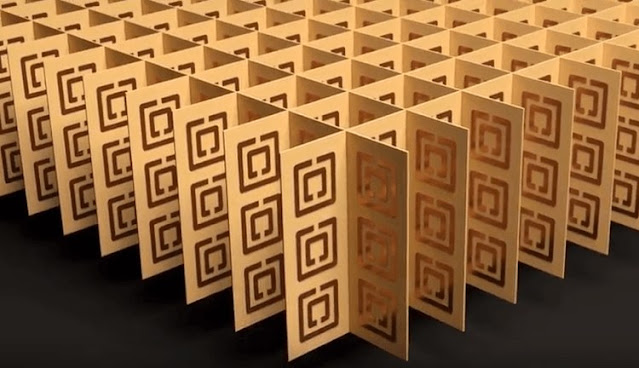

These kinds of tunable materials are very exciting and can be used to create devices that have a multitude of functions, such as waveguides that can direct and slow the flow of sound or vibration insulators that can protect sensitive equipment from damaging effects. To achieve these designs, engineers use a computer-aided design (CAD) system to create geometrical patterns that contain the building blocks of this material.

These are often repeating grids of cellular components, with a cell size roughly equal to the wavelength of electromagnetic radiation they want to work with. Generally, these structures are modeled using implicit modeling in the design software. This allows the designer to create complex geometries that are not possible with typical CAD systems.

Many of the best design tools now include implicit modeling capabilities that can scale to large Metamaterials component designs. This can significantly speed up the process of creating material designs, thereby improving overall design speed and quality.

Comments

Post a Comment