Liquid Silicone Rubber; Used to Make Injection Molded Parts for Products Used In End-Use Industries

Liquid Silicone Rubber is a durable, heat-tolerant, chemically inert material used in a wide variety of industries. It’s also a favorite of medical device manufacturers due to its biocompatibility and hypo-allergenic properties. Injection molding of LSR is an efficient process that can produce precise, complex parts with exceptional detail, accuracy and consistency. It is a two-part, platinum (addition/heat) curable elastomer that can be molded at elevated temperatures, with very fast cycle times and high yields.

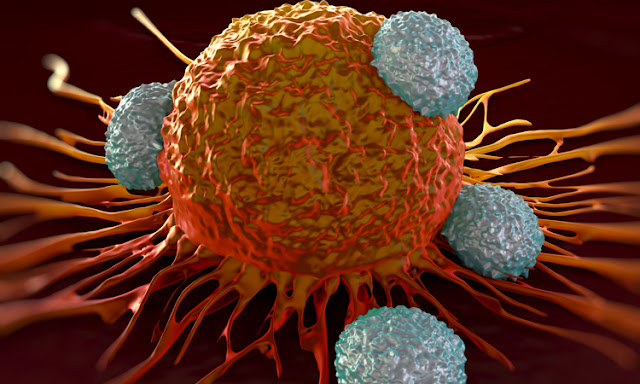

This type of injection molding can be applied to a wide range of shapes and sizes ranging from round, square, and rectangular to more complex geometries. When compared to thermoplastic elastomers (TPEs), LSR is more stable, resistant to chemicals, fire retardant, and has higher temperature resistance, enabling it to be used in applications where other materials would melt, erode or lose their mechanical properties. It is ideal material for medical devices that come in contact with human skin, like prostheses and organ parts.

Over the forecast period (2016-2024), strict rules governing the usage of LSR in medical devices are anticipated to restrain the Liquid Silicone Rubber Market expansion.

It can also be used for products that need to withstand exposure to environmental conditions, such as gaskets and seals in portable communications and data acquisition instruments. LSR ability to be molded and cured at elevated temperatures makes it an excellent choice for a number of industrial applications, including the automotive industry. It is also used in electronic and consumer products (provide an excellent solution for a wide range of electrical applications), gaskets, hardware, and a host of other markets.

LSR is a highly versatile material, and new applications for it are discovered and tested every day. It is a two-part silicone-based polymer used in various end-use industries, such as automotive, appliances, food, textiles, and consumer goods. Thus, there is an increasing demand for LSR. In May 2022, Datwyler’s production plant in Silao, Mexico, become the latest facility to receive an upgrade in order to provide Liquid Silicone Rubber components to its customers in Mexico and the wider North and South American Region.

Comments

Post a Comment